Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

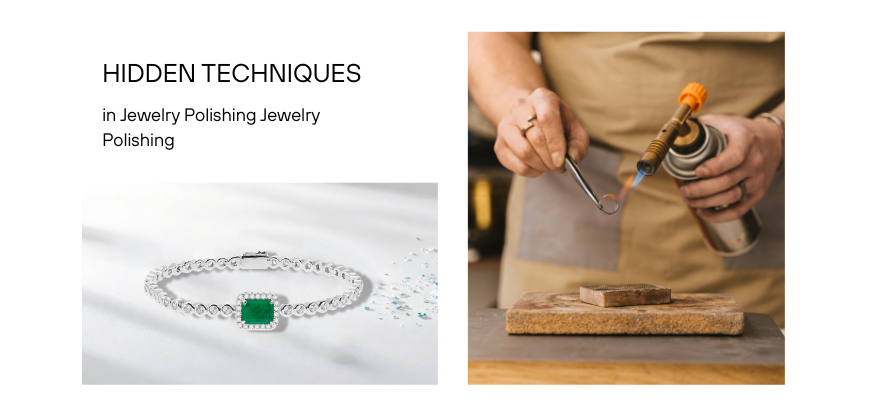

In jewelry manufacturing, polishing is the final process and also the key to determining the texture of the finished product.

Many people think that polishing merely makes the metal surface "brighter", but in fact, it conceals many details that determine the quality behind it.

✨ 1. Polishing, not just "brightening"

True polishing is a micro-level surface adjustment. Each polishing is about correcting minor unevenness and flaws, making the metal surface smoother and more reflective.

High-quality polishing enables light to flow more gently on the surface of jewelry rather than reflecting stiffly.

⚙️ 2. The layering of craftsmanship

At Rachel Jewellery, every piece of jewelry undergoes a multi-level polishing process .

Rough grinding → medium grinding → fine polishing → cleaning → pre-coating inspection. Different materials and different inlay structures all have corresponding pressure and speed requirements.

For instance, 925 silver needs to maintain its brightness while avoiding overheating and deformation, which is a great test of craftsmanship experience.

💡 3. Details determine the final product

When working, polishers often make "manual fine-tuning" for the tiny prong inlay and corner areas. These seemingly insignificant details ultimately determine the overall luster and wearing comfort of the jewelry.

Every polished piece of work seems to have "awakened" the second life of the jewelry. Good design requires precise craftsmanship to be presented.

Rachel Jewellery insists on interpreting quality through craftsmanship. From every polishing detail, it reflects the pursuit of beauty and precision.